Detecting Faults in Underground Electrical Lines

Detecting faults in underground electrical lines is crucial to avoid serious issues. This guide covers the signs and methods to identify problems before they escalate.

Sydney, like many urban areas, relies heavily on underground electrical lines, which, while shielded from such dramatic failures, present their own unique challenges.

Underground electrical lines, essential for urban infrastructure, are buried to protect them from environmental factors and aesthetic concerns. However, when faults occur, they can be particularly difficult to detect and repair, posing significant risks to public safety and causing prolonged power outages.

The complexity of these systems and the potential hazards they carry make prompt and accurate fault detection not just important but critical.

This blog aims to guide readers through the most effective methods for detecting faults in underground electrical lines, ensuring safety and minimising disruptions.

Underground Electrical Faults: An Overview

Underground electrical faults are a significant concern in urban areas, where underground cables are vital for distributing power. Understanding these faults and their implications is crucial for maintaining a reliable power supply.

Definition and Types

An underground cable fault occurs when there is a failure in the continuity or insulation of the power cables beneath the ground, disrupting the flow of electricity. Common types include:

- Open Circuit Faults: These occur when the continuity of the conductor is broken, typically due to physical damage.

- Short Circuit Faults: This type of circuit fault happens when the electrical current bypasses the intended path, often due to a cable insulation breakdown.

- Earth Faults: These occur when the current escapes into the ground, usually due to insulation failure between the live conductor and earth.

Causes

Cable faults can occur due to various factors, such as:

- Environmental Factors: Underground cables can suffer from cable insulation degradation due to soil moisture, temperature changes, and natural aging.

- Accidental Damage: Excavation activities around cable routes can cause accidental damage, leading to faults more frequently.

- Aging: Over time, underground power cables can deteriorate, increasing the risk of high-voltage cable faults.

Consequences

If an underground cable fault goes undetected, it can cause severe issues, including:

- Power Outages: Disruptions in transmission lines can leave entire areas without power.

- Electrical Fires: Short circuit faults and arc reflection can ignite surrounding materials, leading to dangerous fires.

- Safety Hazards: Underground cable faults pose significant risks to public safety, particularly if the fault occurs near populated areas.

Effective fault detection and fault locating techniques, such as time domain reflectometry and the pulse reflection method, can help identify exactly where cable faults have occurred, allowing for timely repairs.

Tools like the domain reflectometer, fault locator, and cable locator are essential in detecting faults and locating them before they lead to more severe consequences.

Visual Inspection: The First Step in Fault Detection

The first step in fault detection for underground cables is a thorough visual inspection of the area where the fault is suspected. This initial assessment is crucial as it can provide immediate clues about the nature and location of the problem, helping to guide further investigation.

Initial Assessment

Conducting a visual inspection allows technicians to quickly identify obvious signs of damage or disturbances that may indicate the presence of a cable fault. This step is significant because it can reveal surface-level issues that might be causing or contributing to the underground cable fault.

Signs to Look For

During the inspection, technicians should look for several tell-tale signs of underground faults:

- Ground Disturbances: Uneven or disturbed ground, particularly in areas where construction or excavation has recently taken place, could signal a fault occurring beneath the surface.

- Burn Marks: Scorch marks or areas of melted ground may indicate a short circuit or high-voltage cable fault.

- Unusual Vegetation Growth: Abnormal or patchy vegetation growth can suggest heat from an underground cable end cable fault, particularly in areas where cables are buried.

Limitations

However, while a visual inspection is an essential first step, it is not sufficient on its own. Many faults underground cannot be seen from the surface, especially those within the cable insulation or deep beneath the ground.

Therefore, visual inspection must be complemented by advanced fault detection techniques, such as the time domain reflection method or domain reflectometer, to accurately locate underground cable faults and ensure a comprehensive diagnosis.

Using Advanced Technology for Accurate Detection

Advanced technology plays a crucial role in the accurate fault detection and fault locating of underground cables. Several tools and methods are employed to enhance the precision and efficiency of locating and diagnosing cable faults.

Cable Locators

Cable locators are essential tools used to identify the exact location of underground power cables. These devices work by transmitting a signal into the cable near the suspected fault area.

A receiver then detects the signal, allowing technicians to trace the path of the underground cables and pinpoint where the fault occurs. Cable locators are invaluable in preventing unnecessary excavation and reducing the risk of damaging other utilities.

Ground Penetrating Radar (GPR)

Ground-penetrating radar (GPR) is another powerful tool for detecting anomalies in underground lines. GPR sends electromagnetic waves into the ground, which reflect back when they encounter different materials, such as a cable fault. This technology is effective in various soil conditions, although its accuracy can be affected by highly conductive soils, such as those with high moisture content.

Time Domain Reflectometry (TDR)

TDR operates on the principle of sending electrical pulses into a power cable and measuring the time it takes for the pulses to reflect back. Any irregularities, such as a short circuit or open circuit fault, cause reflections that can be analysed to determine the fault location. TDR is highly effective for high-voltage cable faults and provides precise cable fault location data.

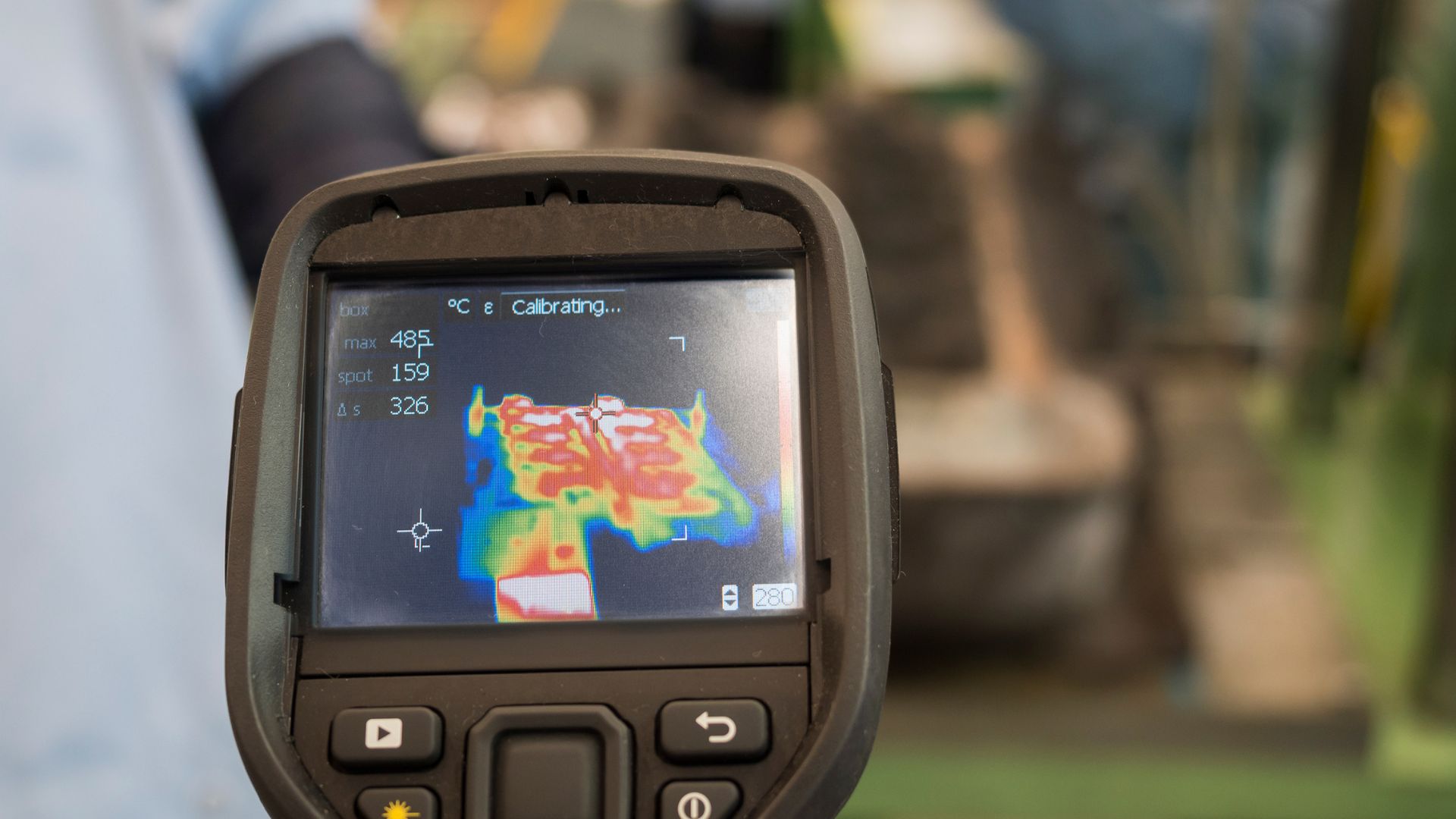

Thermal Imaging

Thermal imaging is used to detect overheating in underground cables, which may indicate a fault. By capturing the heat signature of a cable, thermal cameras can identify hotspots that suggest insulation breakdown or excessive electrical load. This method is particularly useful for monitoring the health of power cables over time.

Comparative Analysis

Each of these technologies has its strengths and limitations.

Cable locators are excellent for identifying cable paths but may not detect the length fault or type of fault. GPR is versatile across different terrains but can be less effective in certain soil types.

TDR offers precise fault detection but requires access to both ends of the cable. Thermal imaging is non-invasive and effective for identifying overheating issues but may not detect all types of faults.

Combining these methods often provides the most comprehensive approach to fault detection in underground cables.

Preventive Measures to Avoid Future Faults

Preventive measures are essential in reducing the risk of cable faults and ensuring the long-term reliability of underground power systems.

Regular Maintenance

Regular inspections and maintenance are critical, even when no faults are apparent. Routine checks help identify potential issues, such as cable insulation wear or minor circuit faults, before they escalate into major problems. This proactive approach minimises downtime and extends the lifespan of underground cables.

Proper Installation

Proper installation techniques are crucial to preventing faults from occurring. Ensuring that power cables are installed with appropriate protection, such as using the correct depth and avoiding sharp bends, reduces the likelihood of damage. Adhering to best practices during installation can prevent short circuits and open circuit faults.

Environmental Considerations

Environmental factors, such as soil type and moisture levels, should be carefully considered during installation. For instance, highly conductive soils can increase the risk of earth faults. Selecting the right materials and employing protective measures based on the local environment will help mitigate these risks.

Upgrading Old Cables

Replacing aging cables with newer, more robust materials is an effective way to prevent future cable faults. Modern cable technologies offer enhanced durability and resistance to environmental stressors, making them a wise investment for long-term reliability.

Ensuring Safe and Reliable Underground Electrical Lines

Ensuring the safety and reliability of underground electrical lines is crucial to preventing power outages and ensuring public safety. Key methods for detecting faults include visual inspections, cable locators, Ground-Penetrating Radar (GPR), Time-Domain Reflectometry (TDR), and thermal imaging. These technologies help accurately identify and locate cable faults, enabling timely repairs that minimise the risk of serious issues like electrical fires or extended outages.

Addressing underground cable faults promptly is essential to avoid disruptions and potential hazards. Regular maintenance, proper installation, and considering environmental factors such as soil type and moisture during installation are vital preventive measures. Additionally, upgrading aging cables with modern, robust materials can significantly reduce the likelihood of future faults.

If you live in Sydney, now is the time to take proactive steps to maintain your underground electrical systems. Regular inspections and preventive maintenance can save you from costly repairs and dangerous situations.

For expert assistance, contact Sydney Level 2 Electricians. Our Level 2 Electricians are specialists in underground service lines, equipped with advanced technology to ensure your systems are safe and reliable. Trust our expertise to handle any underground electrical issue, ensuring a secure and uninterrupted power supply for your home or business.